Is your Triangle Tube boiler acting up and leaving you in the cold? You rely on your boiler to keep your home warm and comfortable, so when problems arise, it can be frustrating and stressful.

Understanding the common issues your Triangle Tube boiler might face can save you time, money, and hassle. You’ll discover the key problems to watch out for, how to spot the warning signs early, and what steps you can take to fix them before they get worse.

Keep reading to protect your heating system and stay cozy all season long.

Common Triangle Tube Boiler Issues

Triangle Tube boilers are known for efficiency and reliability. Still, like any heating system, they can face common issues. Recognizing these problems early helps in keeping your home warm and safe.

This section highlights frequent problems with Triangle Tube boilers. Each issue can affect your boiler’s performance and may require professional care.

Leaks And Drips

Leaks are a common sign of trouble in boilers. Water dripping can come from pipes, valves, or the boiler itself. Small leaks may cause bigger damage over time. Check for rust or wet spots around the unit. Ignoring leaks can lead to costly repairs.

No Heat Or Inconsistent Heating

Sometimes the boiler does not heat at all or heats unevenly. This problem often points to a faulty thermostat or air trapped in the system. It can also be a sign of a broken pump or valve. Without proper heat, your home feels cold and uncomfortable.

Strange Noises

Boilers should run quietly. Strange noises like banging, clanking, or whistling show internal issues. These sounds might come from air in the pipes or limescale build-up. Noises can also mean parts are loose or worn out. Ignoring sounds can worsen the damage.

Pilot Light Problems

The pilot light keeps the boiler running. If it goes out or won’t stay lit, the boiler stops heating. This issue may be due to a dirty pilot, faulty thermocouple, or gas supply problems. A cold home is the result until the pilot light works again.

Pressure Fluctuations

Boiler pressure should stay steady for safe operation. High or low pressure causes the boiler to shut down or work poorly. Common causes include leaks, faulty expansion tanks, or pressure relief valve issues. Monitoring pressure regularly helps prevent breakdowns.

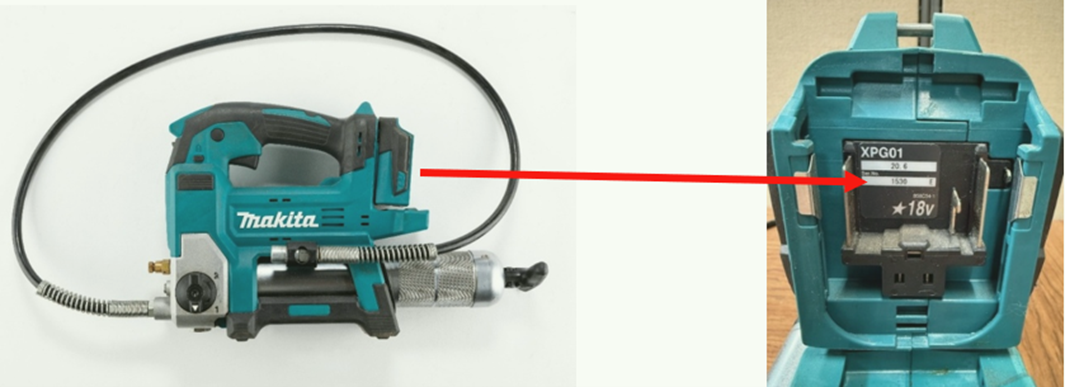

Credit: www.cpsc.gov

Causes Behind Boiler Malfunctions

Understanding the causes behind Triangle Tube boiler malfunctions helps prevent costly repairs. Boilers can stop working well for different reasons. Knowing these reasons makes it easier to spot problems early. Regular checks keep the heating system running smoothly. Below are common causes that often lead to boiler issues.

Air In The System

Air trapped inside the boiler system blocks water flow. This causes uneven heating and strange noises. It also lowers the boiler’s efficiency. Bleeding the radiators can remove trapped air. This simple fix often restores normal function quickly.

Faulty Thermostat

A broken thermostat sends wrong temperature signals. The boiler may not turn on or off at the right times. This causes overheating or no heat at all. Replacing or repairing the thermostat solves this problem. Proper thermostat function ensures comfortable and consistent heat.

Blocked Or Dirty Components

Dirt and debris build-up inside the boiler parts slows down operation. Pipes and heat exchangers can get clogged. This reduces heat output and increases fuel use. Regular cleaning prevents blockages and keeps the system efficient. Cleaning also extends the boiler’s life.

Wear And Tear On Parts

Boiler parts wear out with time and use. Seals, valves, and pumps may start leaking or fail. Old parts cause leaks and reduce heating power. Routine inspections catch worn parts early. Timely replacement stops bigger issues and saves money.

Electrical Failures

Electrical faults can stop the boiler from working. Wiring problems or failed controls disrupt boiler signals. This leads to no heat or unsafe operation. A qualified technician should check electrical components regularly. Fixing these faults keeps the boiler safe and reliable.

Quick Fixes For Triangle Tube Boilers

Triangle Tube boilers can face common problems that stop them from working well. Many issues have easy solutions. Quick fixes help save money and avoid calling a technician. Some simple steps restore your boiler’s heat fast. Follow these easy actions to keep your home warm and cozy.

Bleeding The Radiators

Air trapped in radiators causes cold spots and noise. Use a radiator key to open the valve slowly. Let the air escape until water flows steadily. Close the valve tightly to stop leaks. This improves heating and saves energy.

Resetting The Boiler

A reset can clear minor errors in the boiler system. Locate the reset button on your Triangle Tube boiler. Press and hold it for a few seconds. Wait for the boiler to restart. This often fixes small glitches and restores normal operation.

Replacing Thermostat Batteries

Weak batteries cause poor thermostat response. Open the thermostat cover carefully. Remove old batteries and replace them with new ones. Use the correct battery type recommended by the manufacturer. This ensures better temperature control and comfort.

Cleaning Filters And Vents

Dirty filters block air and reduce efficiency. Turn off the boiler before cleaning. Remove filters and vents gently. Wash them with warm water and mild soap. Dry completely before reinstalling. Clean parts help your boiler run smoothly.

Checking And Adjusting Pressure

Incorrect pressure causes boiler errors and poor heating. Check the pressure gauge on the boiler panel. Ideal pressure is usually between 1 and 2 bar. Adjust the pressure using the filling loop if needed. Keep pressure stable to avoid damage and improve performance.

Credit: www.cpsc.gov

When To Call A Professional

Triangle Tube boilers are reliable, but problems can happen. Knowing when to call a professional helps avoid bigger damage. Some issues need expert care to keep your home safe and warm. Watch for signs that show it’s time to get help.

Persistent Leaks

Small leaks might seem easy to fix. Persistent leaks can cause water damage and lower efficiency. A professional can find hidden leaks and repair them properly. Do not ignore leaking water around the boiler.

Repeated Pressure Drops

Pressure drops affect the boiler’s heating power. If pressure drops often, it may mean a serious issue inside. Experts have the tools to check valves and pipes. Constant pressure loss needs quick attention to avoid failure.

Ignition Failures

The boiler must ignite to work. If it fails to start many times, it shows a fault. Ignition problems can be dangerous if not fixed right. Professionals know how to safely repair ignition systems.

Unusual Smells Or Carbon Monoxide Concerns

Strange smells near the boiler are a red flag. Carbon monoxide is a deadly gas and hard to detect. A professional can test for leaks and fix ventilation issues. Never ignore odd odors or suspected gas leaks.

Preventive Care Tips

Taking care of your Triangle Tube Boiler helps avoid costly repairs. Preventive care keeps the system running smoothly and extends its life. Simple steps can stop common problems early. Follow these tips to protect your boiler.

Regular Maintenance Schedule

Set a regular maintenance plan for your boiler. Check it at least once a year. Clean parts and inspect for leaks or damage. A technician can spot small issues before they grow. This routine saves money and prevents breakdowns.

System Flushing

Flushing removes dirt and buildup inside the boiler. Dirty water causes corrosion and clogs. Flush the system every few years to keep pipes clear. Clean water helps the boiler work efficiently. It also prevents rust and blockages.

Monitoring Boiler Performance

Watch for changes in how your boiler works. Strange noises or uneven heating signal problems. Check pressure and temperature regularly. Early detection helps fix small issues fast. Keep a log to track any changes over time.

Upgrading Old Components

Old parts wear out and cause failures. Replace worn valves, pumps, and controls on time. New components improve safety and performance. Upgrades reduce energy use and repair costs. Stay ahead by updating parts when needed.

Credit: www.youtube.com

Frequently Asked Questions

What Are Common Triangle Tube Boiler Problems?

Triangle Tube boilers often face leaks, ignition failures, and low water pressure issues.

How To Fix Low Water Pressure In Triangle Tube Boilers?

Check for leaks, refill the system, and bleed air from radiators to restore pressure.

Why Does My Triangle Tube Boiler Keep Losing Heat?

Air trapped in pipes or faulty thermostat settings can cause heat loss in these boilers.

How Often Should Triangle Tube Boilers Be Serviced?

Annual servicing helps prevent problems and ensures the boiler runs efficiently and safely.

What Causes Strange Noises In Triangle Tube Boilers?

Noises usually come from air in the system, pump issues, or scaling inside the boiler.

Conclusion

Triangle Tube boiler problems can disrupt your home’s comfort. Regular checks help catch issues early. Clean parts and clear vents keep the system running well. Watch for strange noises or leaks as warning signs. Quick repairs save money and prevent bigger troubles.

Trust simple care to extend your boiler’s life. Stay aware, act fast, and enjoy warm, reliable heat all season.