Are you worried about the reliability of your Toyota’s E CVT system? You’re not alone.

Many Toyota owners face issues that can affect your car’s performance and safety. Understanding these common problems can save you time, money, and stress. You’ll discover what to watch for, how to spot early warning signs, and what steps you can take to keep your vehicle running smoothly.

Keep reading to protect your investment and drive with confidence.

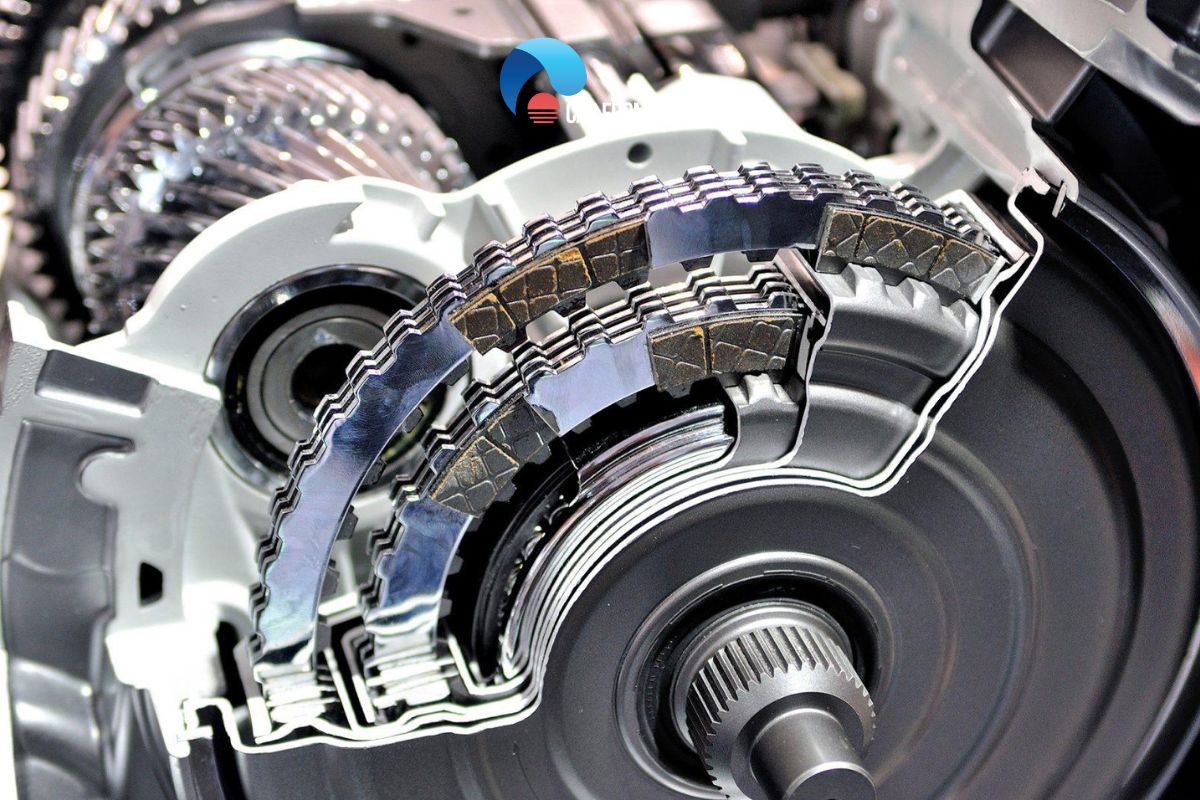

Credit: carfromjapan.com

Common Toyota E Cvt Issues

The Toyota E CVT is known for smooth driving and fuel efficiency. Yet, some common issues may affect its performance. Understanding these problems helps in early detection and repair. This section covers the most frequent Toyota E CVT troubles.

Slipping And Jerking Symptoms

Slipping feels like the car is losing power. Jerking happens during acceleration or gear changes. These symptoms often show wear inside the transmission. They may also indicate low transmission fluid or a faulty clutch.

Overheating Concerns

Overheating can cause serious damage to the E CVT. It usually happens from low fluid levels or clogged cooling systems. The car might lose power or shut down to protect itself. Regular checks of fluid levels help prevent this problem.

Unusual Noises

Strange sounds like whining, grinding, or humming signal trouble. These noises may come from worn bearings or gears. Ignoring these signs can lead to costly repairs. Early inspection can save your transmission from further damage.

Warning Lights And Error Codes

The dashboard may show warning lights for transmission issues. Error codes can be read with a diagnostic tool. These codes help identify the exact problem quickly. Addressing these warnings early avoids bigger problems later.

Causes Behind E Cvt Problems

The Toyota E CVT system offers smooth driving but can face issues over time. Understanding the causes behind E CVT problems helps in timely care. Several factors contribute to these issues, ranging from mechanical wear to electronic faults. Each cause affects the system’s performance differently and needs specific attention.

Fluid Degradation And Leaks

The E CVT depends on special transmission fluid for smooth operation. Over time, this fluid can degrade or leak out. Old fluid loses its ability to lubricate and cool the system. Leaks reduce fluid levels, causing overheating and wear. Regular fluid checks and changes help avoid these problems.

Worn Out Components

The E CVT has many moving parts that wear out with use. Belts, pulleys, and bearings may weaken or break after long drives. Worn parts cause noise, slipping, or poor acceleration. Timely replacement of these components keeps the system running well.

Software And Sensor Malfunctions

Modern E CVT systems rely on software and sensors for control. Faulty sensors can send wrong data to the computer. Software glitches may cause unexpected shifts or jerks. Updating software and fixing sensors prevents these malfunctions.

Driving Habits Impact

Driving style affects the E CVT’s health. Hard acceleration, frequent stops, or towing heavy loads strain the system. Gentle driving reduces stress on parts and fluid. Good habits extend the life of the transmission.

Diagnosing E Cvt Malfunctions

Diagnosing E CVT malfunctions in Toyota vehicles requires a careful approach. The E CVT system controls smooth gear changes and helps fuel efficiency. Problems in this system can cause unusual noises, jerking, or warning lights. Identifying issues early can prevent bigger repairs and higher costs. Follow these steps to check your E CVT system for faults.

Visual Inspection Tips

Start with a visual check under the hood. Look for leaks near the transmission area. Check the CVT fluid level and color. Dark or burnt-smelling fluid signals a problem. Inspect belts and pulleys for damage or wear. Loose or broken parts can cause slipping or noise. Also, observe the transmission casing for cracks or damage.

Using Diagnostic Tools

Use an OBD-II scanner to read error codes from the car’s computer. These codes help pinpoint E CVT faults quickly. Codes related to transmission or sensors often appear. Clear codes after repairs and test drive the car. A professional scanner may give more detailed data. Some apps connect to Bluetooth OBD devices for easy reading.

When To Seek Professional Help

Persistent warning lights or strange noises need expert attention. Difficulty in shifting or slipping indicates serious issues. If fluid leaks continue after topping off, visit a mechanic. Complex E CVT problems require special tools and knowledge. Certified Toyota technicians can diagnose and fix problems safely. Avoid driving long distances with a faulty transmission to prevent damage.

Credit: carfromjapan.com

Expert Repair Strategies

Experts use specific methods to fix Toyota E CVT problems. These strategies keep the transmission working well. Proper care can extend the life of your vehicle. Understanding these repair methods helps owners make smart choices.

Fluid Replacement And Maintenance

Changing the CVT fluid is crucial. Old fluid causes wear and poor shifting. Experts drain the old fluid fully. They use the right type of new fluid. Regular fluid checks prevent many issues. Clean fluid helps keep the transmission cool. This simple step avoids costly repairs later.

Component Repair And Replacement

Some parts wear out and need fixing or replacing. Experts check belts, pulleys, and clutches for damage. Worn components cause slipping and noise. Replacing these parts restores smooth operation. Using original parts ensures proper fit and performance. Skilled technicians know how to access hard parts safely.

Software Updates And Resets

The E CVT system relies on software for control. Sometimes glitches cause shifting problems. Experts update the transmission software to fix bugs. They also reset the system to clear errors. These updates improve response and efficiency. Software care keeps the CVT running smoothly.

Preventive Measures For E Cvt

Preventive measures help keep your Toyota E CVT running smoothly. Taking care of the transmission can avoid costly repairs. Small steps can extend the life of your vehicle’s E CVT. Understanding how to maintain and monitor it ensures better performance over time.

Regular Maintenance Schedule

Follow the manufacturer’s recommended service intervals. Change the transmission fluid as advised. Clean fluid helps the E CVT work well. Check for leaks or worn parts during routine visits. Proper maintenance prevents buildup and wear inside the system.

Driving Practices To Avoid Damage

Avoid sudden acceleration or hard braking. These actions stress the transmission parts. Drive smoothly and keep steady speeds. Do not overload your vehicle beyond limits. Gentle driving reduces heat and friction inside the E CVT.

Monitoring Warning Signs Early

Listen for unusual noises or vibrations while driving. Watch for slipping or delayed acceleration. Check if the transmission warning light appears on the dashboard. Early detection helps fix issues before they worsen. Report any problems to a mechanic quickly.

Owner Experiences And Advice

Many Toyota owners share their experiences with E CVT problems. These stories help others understand what to expect and how to handle issues. Honest advice from real users often proves more helpful than manuals or ads. Listening to owners reveals common troubles and useful fixes.

Below are key points from Toyota E CVT users. Their tips can save time and money.

Common Owner Complaints

Some owners report strange noises from the transmission. Others mention jerking or hesitation during acceleration. A few notice warning lights on the dashboard. Overheating of the CVT system is another issue. These problems often appear after driving many miles. Regular maintenance sometimes does not prevent them.

Successful Fixes And Tips

Many owners found that changing the CVT fluid helps. Using the right type of fluid is very important. Some fixed noises by replacing worn belts inside the CVT. Keeping the transmission cool prevents overheating. Avoid heavy towing or rapid acceleration to reduce stress. Early detection of problems saves costly repairs.

Choosing The Right Service Center

Not all mechanics understand E CVT systems well. Owners recommend choosing service centers with CVT experience. Certified Toyota dealers are often reliable choices. Ask if the shop uses the right tools and genuine parts. Check reviews from other Toyota owners before deciding. A good service center helps extend the life of your CVT.

Credit: www.topspeed.com

Frequently Asked Questions

What Are Common Toyota E Cvt Problems?

Toyota E CVT often faces issues like overheating, belt wear, and hesitation during acceleration.

How To Identify Toyota E Cvt Transmission Issues?

Look for slipping gears, strange noises, or delayed acceleration as signs of E CVT problems.

Can Toyota E Cvt Problems Cause Engine Damage?

Yes, ignoring E CVT issues can lead to engine strain and possible damage over time.

How Often Should Toyota E Cvt Fluid Be Changed?

Toyota recommends changing E CVT fluid every 60,000 to 100,000 miles for smooth performance.

Is Toyota E Cvt Repair Expensive?

Repair costs vary, but fixing E CVT problems can be costly due to complex parts.

Conclusion

Toyota E CVT problems can affect your driving experience and car’s health. Knowing common issues helps you spot trouble early. Regular maintenance keeps the transmission running smoothly. Addressing problems quickly avoids costly repairs later. Stay informed and check your vehicle often.

Driving safely means less stress and longer car life. Take care of your Toyota to enjoy many miles ahead. Simple steps make a big difference in performance and reliability. Keep an eye on warning signs and act fast. Your car will thank you.