Are you noticing rough idling, strange noises, or a drop in your vehicle’s performance? These could be signs of GM cylinder deactivation problems affecting your engine.

If you rely on your GM vehicle for daily drives, understanding these issues is crucial to keeping it running smoothly. You’ll discover what causes cylinder deactivation problems, how they impact your car, and what you can do to fix them before they turn into costly repairs.

Keep reading to protect your ride and get back on the road with confidence.

Credit: www.youtube.com

Common Causes Of Gm Cylinder Deactivation Issues

GM cylinder deactivation helps save fuel by shutting off some engine cylinders. Problems with this system can cause rough running and lower fuel efficiency. Understanding the common causes of these issues can help spot and fix problems fast.

Faulty Solenoids

Solenoids control the opening and closing of engine valves. If solenoids fail, cylinders may not deactivate properly. This causes engine misfires and poor fuel economy. Solenoids can wear out or get stuck over time.

Oil Flow Problems

The cylinder deactivation system relies on engine oil to work. Low or dirty oil can block flow to the lifters. This stops the system from activating or deactivating cylinders as needed. Regular oil changes keep oil flow smooth.

Electrical Wiring Faults

Wiring connects sensors and solenoids to the engine control module. Broken or damaged wires cause signal loss or errors. This leads to failed cylinder deactivation or false warnings. Checking wiring helps avoid these electrical faults.

Engine Control Module Errors

The engine control module (ECM) manages cylinder activation. Software glitches or hardware faults in the ECM affect this control. Faulty ECMs can cause wrong signals to the solenoids. Updating or replacing the ECM may solve the issue.

Low Oil Pressure

Low oil pressure stops the cylinder deactivation system from working right. The system needs enough pressure to move lifters and deactivate cylinders. Low pressure often links to worn pumps or leaks. Monitoring oil pressure helps keep the system functional.

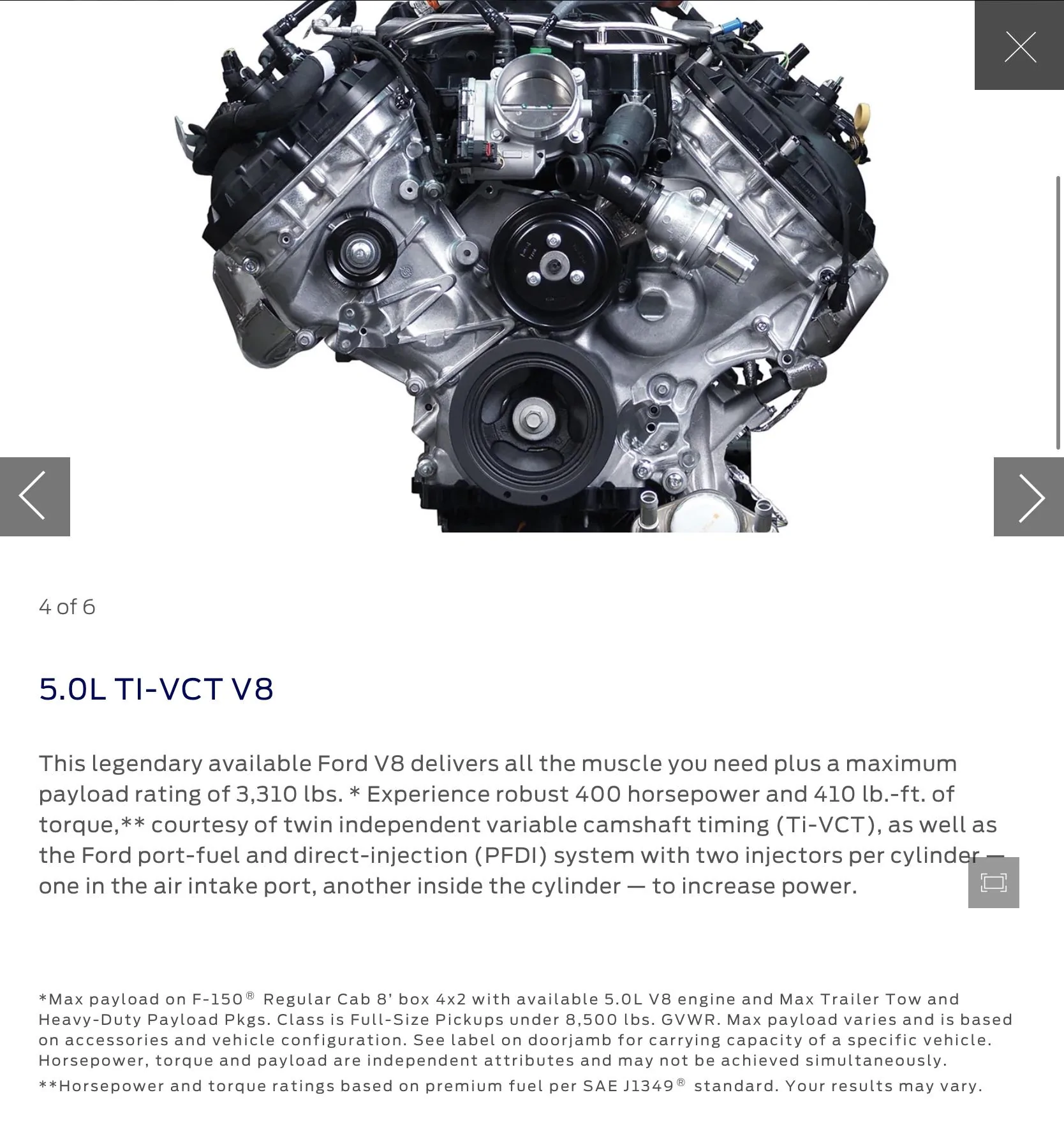

Credit: www.f150gen14.com

Symptoms Of Cylinder Deactivation Failures

Cylinder deactivation helps save fuel by shutting off some cylinders during light engine load. Problems with this system can cause several noticeable symptoms. Recognizing these signs early can prevent bigger engine issues. Below are common symptoms of cylinder deactivation failures.

Rough Idling

The engine may run unevenly when idling. You might feel vibrations or shaking inside the vehicle. This happens because some cylinders do not deactivate properly. The engine struggles to keep a smooth idle speed.

Reduced Fuel Efficiency

Fuel economy often drops with cylinder deactivation problems. The engine uses more fuel than usual. This occurs because all cylinders stay active even when not needed. The system loses its ability to save fuel effectively.

Check Engine Light Activation

The check engine light can turn on suddenly. It signals a problem with the cylinder deactivation system. The vehicle’s computer detects issues and alerts the driver. A diagnostic scan can identify specific faults.

Unusual Engine Noises

You may hear knocking or tapping sounds from the engine. These noises occur when cylinders fail to deactivate correctly. The irregular firing causes the engine to produce strange sounds. It is a clear sign of malfunction in the system.

Diagnostic Steps For Cylinder Deactivation Problems

Diagnosing cylinder deactivation problems in GM vehicles requires careful steps. These steps help identify the root cause quickly. Accurate diagnosis prevents costly repairs and keeps the engine running smoothly.

The process starts with scanning the car’s computer system. Then, a physical check of parts follows. Testing key components confirms if they work as intended. Finally, checking oil condition helps ensure proper engine function.

Using Obd-ii Scanners

Use an OBD-II scanner to read trouble codes from the engine control unit. These codes point to specific cylinder deactivation issues. The scanner shows real-time data about solenoid and sensor performance. It helps to narrow down the problem fast.

Visual Inspection Of Components

Look for damaged or loose wires around the cylinder deactivation system. Check solenoids for cracks or corrosion. Inspect connectors for dirt or moisture. Damaged parts can cause the system to fail or work intermittently.

Testing Solenoid Functionality

Test the solenoids with a multimeter to check resistance. Compare readings to manufacturer specifications. Use a power source to activate solenoids and listen for clicking sounds. Proper solenoid function is key to cylinder deactivation.

Checking Oil Levels And Quality

Low or dirty oil can affect the cylinder deactivation system. Check the oil level using the dipstick. Look for oil color and consistency. Change oil if it is dark or thick. Clean oil helps solenoids and valves work smoothly.

Credit: www.hotrod.com

Effective Fixes For Gm Cylinder Deactivation

Effective fixes for GM cylinder deactivation problems can restore engine performance and smooth operation. Addressing these issues promptly avoids costly repairs and keeps your vehicle running well. Several common solutions target the main causes of cylinder deactivation failure.

Simple repairs and part replacements often solve the problem without much hassle. Understanding these fixes helps you make informed decisions about your vehicle’s care.

Replacing Faulty Solenoids

Solenoids control the cylinder activation process. Faulty solenoids can cause misfires or engine hesitation. Replacing damaged solenoids restores proper cylinder function. Use high-quality parts designed for your GM model. This fix often improves engine smoothness and fuel efficiency.

Repairing Wiring And Connectors

Wiring and connectors carry signals to solenoids and sensors. Loose or damaged wires disrupt cylinder deactivation. Inspect wiring harnesses for wear and corrosion. Repair or replace broken connectors to ensure good electrical flow. Proper wiring fixes prevent engine errors and warning lights.

Updating Engine Control Software

Modern GM engines rely on software for cylinder management. Outdated software can cause incorrect cylinder activation. Updating the engine control unit software ensures compatibility and smooth operation. This fix often clears error codes and improves fuel economy. Visit an authorized service center for software updates.

Ensuring Proper Oil Maintenance

Clean oil is essential for the cylinder deactivation system. Dirty or low oil causes solenoids to stick or malfunction. Regular oil changes keep the system lubricated and clean. Use the oil type recommended by GM for best results. Proper oil care extends engine life and prevents deactivation issues.

Maintenance Tips To Prevent Cylinder Deactivation Issues

Preventing cylinder deactivation problems in GM engines requires regular care. Simple maintenance steps help avoid costly repairs. Following these tips keeps the system working well and extends engine life.

Regular Oil Changes

Clean oil keeps engine parts moving smoothly. It prevents sludge buildup that can block cylinder deactivation valves. Change oil as the manual suggests. Use the right type and amount for your engine.

Periodic System Checks

Inspect the cylinder deactivation system regularly. Look for leaks, worn parts, or electrical issues. Early detection stops small problems from growing. Use diagnostic tools or visit a trusted mechanic.

Using Manufacturer-recommended Parts

Use parts made for your GM model. Generic parts may not fit or work correctly. This can cause the system to fail or perform poorly. Always choose OEM or approved replacements for best results.

Monitoring Engine Performance

Pay attention to how your engine runs. Notice strange noises, rough idling, or loss of power. These signs may indicate cylinder deactivation problems. Address them quickly to avoid bigger damage.

Expert Advice For Long-term Reliability

Maintaining the GM cylinder deactivation system ensures your engine runs smoothly over time. Expert advice helps avoid costly repairs and keeps the system reliable. Understanding key steps improves the lifespan of your vehicle’s engine. Here are essential tips for long-term reliability.

When To Seek Professional Help

Some cylinder deactivation problems need expert attention. Strange noises or engine misfires are clear signs. Avoid delaying repairs to prevent bigger damage. Professionals have the tools and knowledge to fix issues right.

Choosing Quality Replacement Parts

Use only genuine or high-quality parts for repairs. Low-quality parts may fail quickly and cause more problems. Good parts fit better and last longer. This choice saves money and keeps your engine healthy.

Importance Of Timely Repairs

Fix problems as soon as they appear. Small issues can grow into costly repairs. Timely repairs keep the engine running efficiently. Delays can lead to poor fuel economy and engine wear.

Avoiding Common Diy Mistakes

DIY repairs on cylinder deactivation can be tricky. Avoid guessing or skipping steps during fixes. Incorrect repairs can harm the engine or system parts. Trust professionals for complex tasks to ensure safety and success.

Frequently Asked Questions

What Causes Gm Cylinder Deactivation Problems?

Faulty lifters, oil issues, and wiring problems often cause cylinder deactivation faults.

How To Know If Gm Cylinder Deactivation Is Failing?

You might hear engine noise, feel rough idling, or see the check engine light.

Can Bad Oil Affect Gm Cylinder Deactivation?

Yes, dirty or low oil can stop the system from working properly.

Is Cylinder Deactivation Bad For Gm Engine Health?

No, it saves fuel but ignoring problems can lead to engine damage.

How To Fix Gm Cylinder Deactivation Issues Quickly?

Check oil level, inspect wiring, and replace faulty lifters or solenoids.

Conclusion

GM cylinder deactivation problems can affect your engine’s performance. These issues often cause rough idling and lower fuel efficiency. Regular checks help spot problems early. Fixing them quickly saves time and money. Understanding these common faults keeps your vehicle running smoothly.

Stay aware and maintain your engine well. This way, you avoid bigger repairs later. Simple care leads to better driving and fewer troubles. Keep your GM engine healthy for longer.