Is your Everstart air compressor suddenly not working when you need it most? It’s frustrating, especially when you rely on it for quick tasks like inflating tires or powering tools.

You might feel stuck, unsure of what went wrong or how to fix it. But don’t worry—this guide will help you understand why your compressor isn’t starting and what simple steps you can take to get it back up and running.

Keep reading, and you’ll soon have your Everstart working like new again.

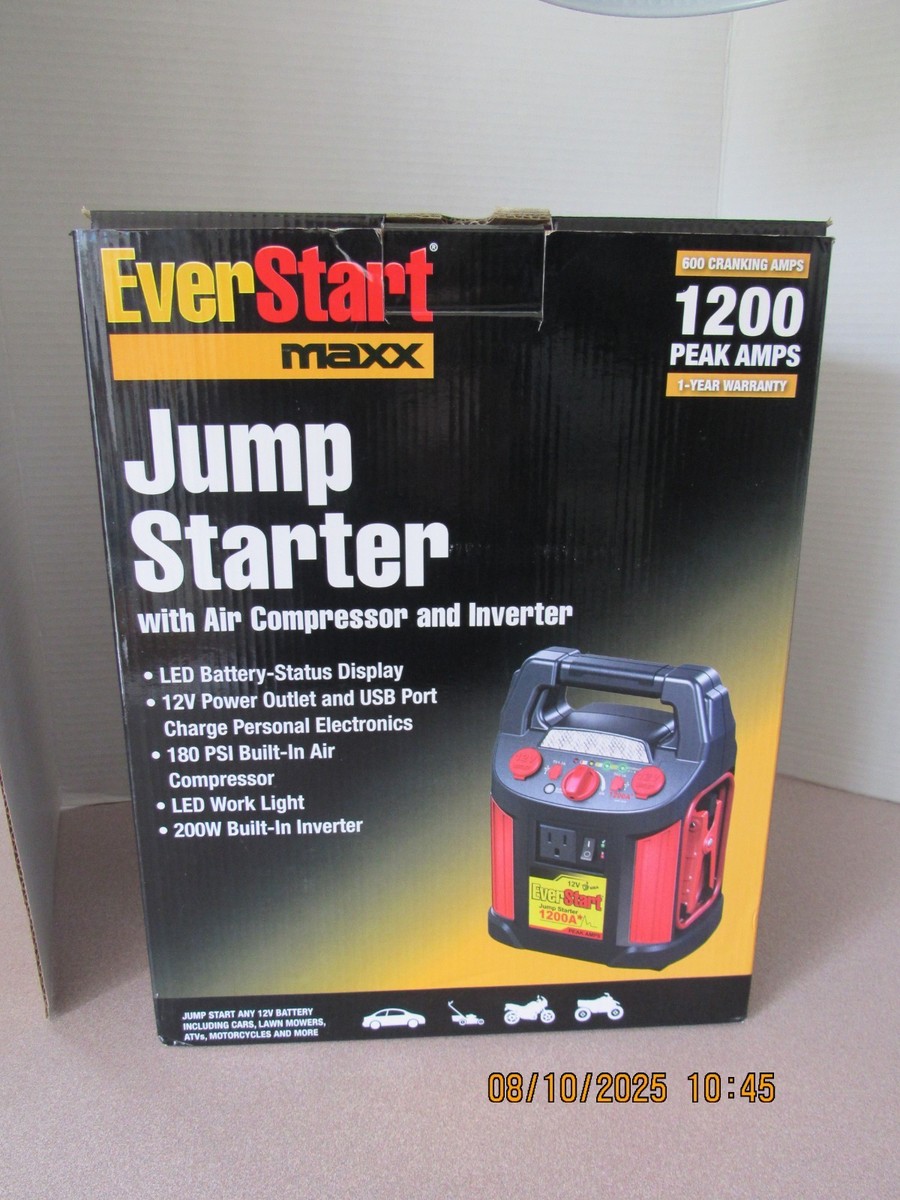

Credit: www.ebay.com

Common Air Compressor Issues

Everstart air compressors can stop working due to several common problems. Knowing these issues helps in quick fixing. Most problems are simple and can be checked without special tools.

Understanding these common faults saves time and money. It also keeps your air compressor running smoothly for longer.

Power Supply Problems

Power supply issues are the top reason an air compressor fails. Check the power cord and plug for damage. Make sure the outlet works by testing another device. Sometimes, a blown fuse or tripped breaker stops power flow.

Pressure Build-up Failures

The compressor must build pressure to work well. If it does not, the pressure switch might be faulty. This switch controls the compressor’s on and off cycles. Dirt or debris in the valve can also block pressure build-up.

Motor Malfunctions

The motor drives the compressor pump. If it does not run, the motor may have a problem. Overheating or worn-out parts cause motor failure. Listen for strange noises or check if the motor gets very hot during use.

Air Leaks

Leaks reduce the compressor’s efficiency. Check hoses, fittings, and the tank for air leaks. Use soapy water to find bubbles where air escapes. Fix leaks quickly to keep pressure steady and avoid extra work for the motor.

Credit: www.walmart.com

Quick Checks Before Repair

Before starting any repair on your Everstart air compressor, try some quick checks. These steps save time and might fix the problem fast. Sometimes, the issue is simple and easy to spot.

Inspect Power Source

Check if the compressor is plugged in properly. Look for loose or damaged power cords. Test the outlet by plugging in another device. A faulty power source can stop the compressor from working.

Check Air Filter

Examine the air filter for dirt and dust. A clogged filter reduces airflow and pressure. Clean or replace the filter if it looks dirty. This can improve the compressor’s performance quickly.

Examine Pressure Switch

The pressure switch controls the compressor’s on and off cycles. Check if it moves freely and is not stuck. A broken switch can prevent the compressor from starting. Adjust or replace the switch if needed.

Look For Visible Damage

Search for cracks, leaks, or worn parts on the compressor. Damage can cause air loss and reduce power. Tighten loose fittings and replace broken parts. Visible damage often points to the problem source.

Simple Fixes To Try

Simple fixes can often solve your Everstart air compressor issues fast. These quick checks save time and money. Try these easy steps before calling for help. Most problems come from small, common faults. Follow the steps below to get your compressor running again.

Resetting The Compressor

Find the reset button on your compressor. It is usually red and easy to spot. Press and hold it for a few seconds. This can clear any electrical faults. Let the compressor cool down if it overheated. After resetting, turn the unit on to test it. This simple step fixes many power issues.

Replacing The Air Filter

A dirty air filter blocks airflow. This makes the compressor work harder or stop. Locate the air filter cover and remove it. Take out the old filter and check for dirt. Replace it with a new, clean filter. This improves air flow and compressor performance. Clean filters help your compressor last longer.

Tightening Loose Connections

Loose connections cause power loss or leaks. Check all bolts and screws on your compressor. Use a wrench or screwdriver to tighten them. Also, inspect electrical wires for secure fittings. Tight connections ensure proper power and air flow. Regular checks prevent breakdowns and keep the compressor safe.

Fixing Air Leaks

Air leaks reduce compressor efficiency. Listen for hissing sounds around hoses and fittings. Spray soapy water on joints to find leaks. Bubbles show where air escapes. Tighten or replace damaged hoses and fittings. Seal leaks with proper tape or sealant. Fixing leaks improves pressure and saves energy.

Credit: www.ebay.com

When To Replace Parts

Knowing when to replace parts in your Everstart air compressor saves time and money. Parts wear out over time and cause poor performance. Timely replacement keeps your compressor working well. Watch for signs that tell you a part needs changing.

Ignoring worn parts can lead to bigger problems. Checking parts regularly helps catch issues early. Here are key parts to watch and when to replace them.

Motor Replacement Signs

The motor is the heart of your air compressor. Strange noises or burning smells mean trouble. If the motor won’t start or stops often, replacement may be needed. Overheating motors or slow running also need attention. Check these signs to avoid total failure.

Pressure Switch Issues

The pressure switch controls compressor pressure. If your compressor won’t stop or start properly, the switch may fail. Fluctuating pressure or no air pressure builds up are warning signs. Replace the switch if it does not respond or trips often. This keeps pressure steady and safe.

Worn Out Hoses

Hoses carry air from the compressor to tools. Cracks, leaks, or bulges in hoses reduce air flow. Air leaks cause poor tool performance and waste energy. Replace hoses with visible damage or leaks. New hoses improve efficiency and safety during use.

Damaged Valves

Valves regulate air flow inside the compressor. Damaged valves cause loss of pressure and uneven air delivery. If you hear hissing or see pressure drops, check valves. Replace valves that stick or leak. Good valves ensure steady and strong air output.

Maintenance Tips For Longevity

Keeping your Everstart air compressor in good shape helps it last longer. Regular care stops common problems. It also keeps the machine running safely and efficiently. Follow these simple maintenance tips to extend your compressor’s life.

Regular Cleaning

Dust and dirt block air flow and cause damage. Wipe the compressor’s exterior often. Clean the air filter to stop clogs. A clean machine works better and lasts longer.

Proper Storage

Store the compressor in a dry place. Avoid areas with extreme heat or cold. Keep it away from moisture to prevent rust. Proper storage protects the parts and keeps the compressor ready to use.

Routine Inspections

Check hoses and connections regularly for leaks. Look for worn or cracked parts. Tighten loose bolts and screws. Early fixes stop bigger problems and keep your compressor safe.

Lubrication Practices

Some Everstart models need oil to run smoothly. Check the oil level often and refill if low. Change the oil as the manual says. Good lubrication reduces wear and keeps the motor cool.

Safety Precautions

Safety is key when dealing with an Everstart air compressor not working. Taking the right steps protects you and your equipment. Follow these safety tips closely to avoid accidents and damage.

Handling Electrical Components

Always disconnect power before inspecting electrical parts. Use insulated tools to avoid shocks. Never touch wires with wet hands. Check cords for damage before use. Replace frayed or broken wires immediately.

Avoiding Overpressure

Do not exceed the compressor’s pressure limit. Overpressure can cause tank bursts or injuries. Use the pressure gauge to monitor air levels. Release excess air safely after use. Keep valves clean and functioning properly.

Using Protective Gear

Wear safety glasses to protect your eyes. Use gloves to prevent cuts and burns. Hearing protection is important in noisy environments. Wear closed-toe shoes to guard your feet. Dress in long sleeves for skin protection.

Safe Repair Practices

Work in a well-ventilated area with good lighting. Follow the user manual for repair instructions. Use the correct tools for each task. Avoid rushing repairs to prevent mistakes. Test the compressor carefully after fixing.

Frequently Asked Questions

Why Is My Everstart Air Compressor Not Turning On?

Check the power source and ensure the compressor is plugged in properly.

How To Fix An Everstart Air Compressor That Won’t Start?

Inspect the fuse, pressure switch, and motor for any faults or damage.

What Causes Everstart Air Compressor To Lose Pressure Quickly?

Leaks in hoses or fittings often cause rapid pressure loss in the tank.

Can A Clogged Air Filter Stop Everstart Compressor Working?

Yes, a dirty filter can block airflow and prevent the compressor from running.

How Often Should I Maintain My Everstart Air Compressor?

Regular maintenance every 3-6 months keeps the compressor running smoothly and safely.

Conclusion

Troubleshooting an Everstart air compressor can save time and money. Check power sources, fuses, and hoses first. Clean or replace dirty filters to improve airflow. Tighten loose connections to avoid leaks. Regular maintenance keeps your compressor working well. Small fixes often solve common problems fast.

Stay calm and follow simple steps carefully. You can get your air compressor running again soon. Don’t give up—help is often close by.