Is your Breville pressure gauge not working, leaving you unsure about your espresso’s perfect pressure? You rely on that gauge to brew rich, flavorful coffee every time.

When it fails, it can be frustrating and confusing. But don’t worry—you’re not alone, and there are simple steps you can take to fix it. Keep reading to discover why your gauge might be acting up and how to get it back on track, so you can enjoy your coffee just the way you like it.

Credit: www.reddit.com

Common Pressure Gauge Issues

The pressure gauge on your Breville machine helps control the brewing process. It shows the pressure inside the machine. This is important for making good coffee. Sometimes, the gauge stops working or shows wrong numbers. This can cause poor coffee quality or damage to the machine.

Knowing the common problems can help you fix the gauge or decide if you need a replacement. It also helps avoid bigger issues later. Below are some signs and causes of pressure gauge problems.

Signs Of A Faulty Gauge

The gauge needle does not move at all during brewing. It stays stuck in one place. This means the gauge is not reading pressure. The needle might jump wildly or move erratically. This shows an unstable or broken gauge. Sometimes, the gauge shows zero pressure even when the machine is on. This is another sign of failure.

Leaks or cracks around the gauge area can also affect its work. You may notice steam or water near the gauge. The coffee may taste weak or burnt due to wrong pressure. These signs point to a faulty pressure gauge.

Causes Of Pressure Gauge Failure

The gauge can fail due to dirt or coffee oils clogging its parts. Regular cleaning is important to keep it working well. Mechanical wear and tear happen after long use. The spring or needle inside the gauge can break or lose tension.

Exposure to high heat and steam can damage the gauge over time. Sometimes, a sudden impact or drop can harm the gauge. Faulty installation or loose connections also cause wrong readings.

Using wrong cleaning tools or harsh chemicals may damage the gauge surface or parts. Regular maintenance and careful handling help prevent these issues.

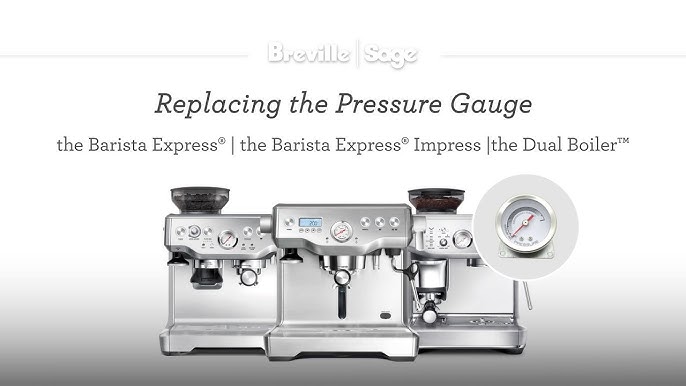

Credit: www.youtube.com

Quick Fixes For Pressure Gauge

The pressure gauge on your Breville machine helps control the brewing process. Sometimes, it may stop working or show incorrect readings. Quick fixes can save time and avoid costly repairs. These easy steps help get the gauge back to normal without hassle.

Resetting The Gauge

Start by turning off the machine. Wait a few minutes to let it cool down. Switch it back on to see if the gauge resets. This simple reset can fix minor glitches. If the gauge still acts strange, try the next step.

Cleaning And Maintenance

Dirt and coffee oils can block the gauge. Use a soft cloth to wipe the surface gently. Clean the area around the gauge carefully. Avoid harsh chemicals that may damage parts. Regular cleaning keeps the gauge accurate and extends its life.

Checking Connections

Loose or damaged connections cause false readings. Unplug the machine before checking. Look for loose wires or parts near the gauge. Tighten any loose screws or connectors. If parts seem broken, replace them to restore function.

When To Replace The Gauge

The pressure gauge on a Breville machine shows the pressure level during brewing. It helps ensure the coffee is made at the right pressure for best taste. Sometimes, the gauge stops working or gives wrong readings. Knowing when to replace it saves time and keeps your machine working well.

Identifying Irreparable Damage

Look for cracks or breaks on the gauge face. Check if the needle moves freely. If it sticks or stays at zero, the gauge may be broken. Water or steam inside the gauge means it is damaged. Electrical faults inside the gauge cannot be fixed. These signs show the gauge needs replacement, not repair.

Choosing The Right Replacement Part

Use the exact gauge model made for your Breville machine. Check the pressure range matches the original part. Buy from trusted sellers or Breville directly. Avoid cheap or generic gauges that may not fit. Proper installation helps the gauge last longer and work accurately. Read the manual or follow guides for replacement steps.

Expert Tips For Longevity

Keeping your Breville pressure gauge working well takes effort. Small steps help it last longer. Follow expert tips to protect your machine. These tips keep your gauge accurate and safe.

Regular Maintenance Practices

Clean the pressure gauge regularly. Use a soft cloth to wipe dirt and steam. Avoid harsh chemicals that can damage parts. Check for blockages in the steam vent. Clear any buildup to keep pressure steady. Replace worn seals and gaskets on time. This prevents leaks and keeps the gauge working well.

Safe Usage Habits

Do not overfill the water tank. Too much water can harm the pressure system. Always use the correct settings for your coffee. Avoid forcing the machine to work too hard. Turn off the machine after use to cool down. Handle the gauge gently to avoid damage. These habits help your Breville pressure gauge last longer.

Troubleshooting Other Breville Pressure Issues

Troubleshooting other Breville pressure issues can help restore your machine’s performance. Pressure problems often arise from parts beyond the gauge. Checking these areas can save you time and repair costs.

Start by examining the pump and boiler. These parts control pressure and heat. Problems here affect espresso quality and machine function. Understanding common issues helps you fix them quickly.

Pump Problems

The pump pushes water through coffee grounds. If your machine has low pressure, the pump might be weak or broken. Listen for unusual sounds or silence during brewing. A noisy or silent pump often means trouble.

Check for blockages in water lines. Mineral buildup can clog the pump and reduce pressure. Cleaning or replacing the pump may be necessary. Simple maintenance can improve pump life and pressure consistency.

Boiler Malfunctions

The boiler heats water to the right temperature and pressure. A faulty boiler causes pressure drops or no pressure at all. Look for leaks or strange noises near the boiler area.

Thermostat or heating element failure can stop the boiler from working. This stops pressure build-up and affects espresso extraction. Testing the boiler with a multimeter helps find electrical issues. Repair or replace faulty parts to restore pressure.

Credit: www.reddit.com

Frequently Asked Questions

Why Is My Breville Pressure Gauge Not Moving?

The gauge might be clogged or damaged, blocking pressure reading. Cleaning or replacing it helps.

How Do I Fix A Stuck Breville Pressure Gauge?

Try cleaning the gauge and its tube gently. Replace if it stays stuck.

Can Low Water Affect The Breville Pressure Gauge?

Yes, low water can cause low pressure, making the gauge show wrong readings.

Does Scale Buildup Cause Breville Pressure Gauge Issues?

Scale can block pressure flow and damage the gauge. Regular descaling is needed.

When Should I Replace My Breville Pressure Gauge?

Replace if it doesn’t move, shows wrong pressure, or leaks steam during use.

Conclusion

A Breville pressure gauge not working can be frustrating. Check the gauge for dirt or damage first. Sometimes, cleaning solves the problem quickly. If it still fails, consider replacing the gauge. Regular maintenance helps keep your machine in good shape.

Taking small steps can save you time and money. Don’t ignore pressure issues; they affect your coffee’s taste. Simple care keeps your Breville running smoothly and your coffee perfect. Keep an eye on your machine and enjoy every cup.