If you drive a Peterbilt truck, you know how important every part is to keep your rig running smoothly. One critical component you might not think about until it causes trouble is the CECU—Central Electronic Control Unit.

When your Peterbilt CECU starts acting up, it can lead to frustrating problems that slow you down or even stop you on the road. You’ll discover the common issues with Peterbilt CECUs, how to spot the warning signs early, and what steps you can take to fix them before they become costly headaches.

Keep reading to protect your truck and keep your journey on track.

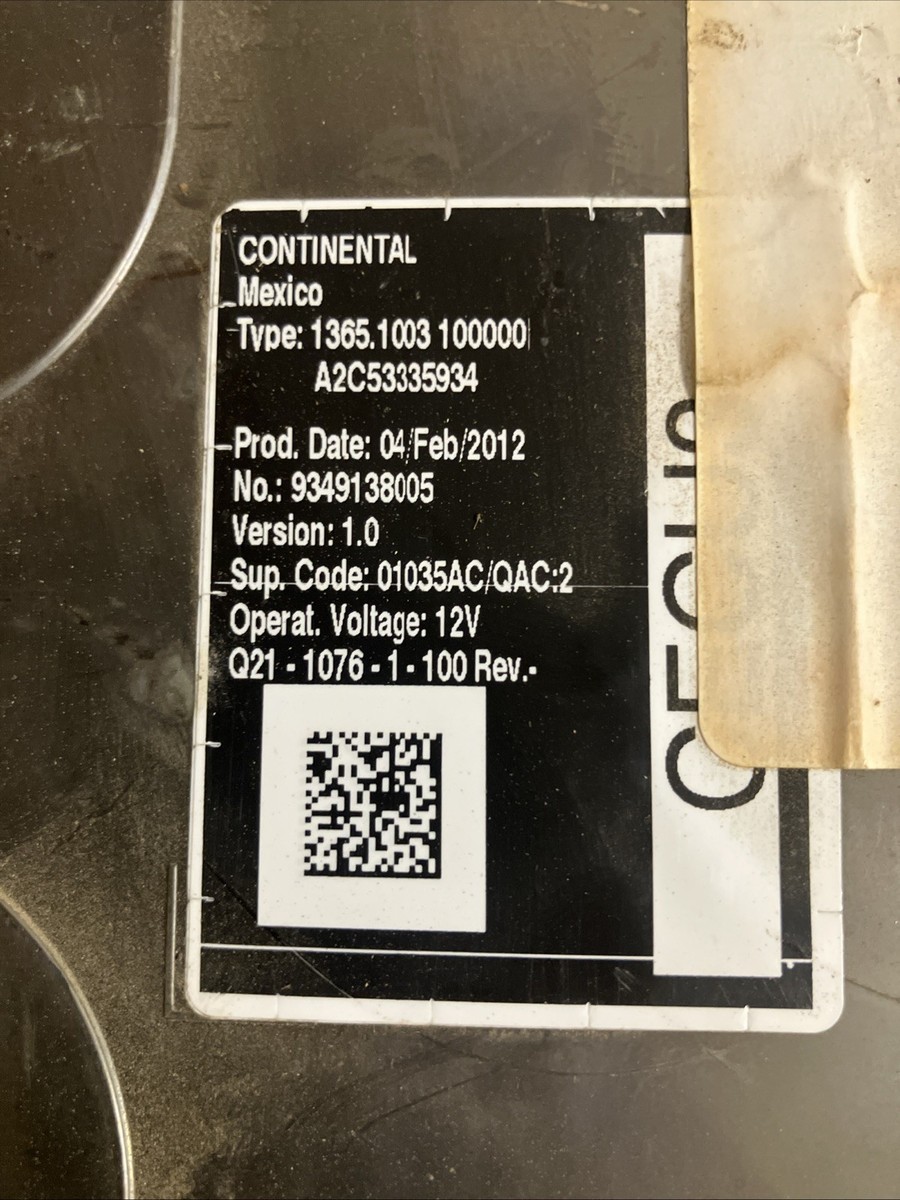

Credit: www.ebay.com

Common Cecu Issues

Peterbilt trucks rely on the Central Electronic Control Unit (CECU) to manage many key functions. Problems with the CECU can cause serious issues. Recognizing common problems helps drivers and mechanics fix trucks faster.

CECU issues affect performance and safety. Knowing typical faults can save time and money on repairs.

Frequent Error Codes

Error codes appear on the dashboard to signal CECU problems. Common codes include communication failures and sensor errors. These codes help identify where the fault lies. Reading error codes is the first step in troubleshooting.

Communication Failures

The CECU must talk to other truck modules. Communication failures cause data loss and system errors. Wiring issues or damaged connectors often cause these failures. Fixing communication restores proper truck functions.

Power Supply Problems

The CECU needs steady power to work correctly. Power supply problems cause the unit to reset or shut down. Loose battery connections or blown fuses are common causes. Checking power sources helps maintain CECU health.

Sensor Malfunctions

The CECU depends on sensors to monitor truck status. Sensor malfunctions send wrong information to the unit. Dirty, damaged, or disconnected sensors often cause errors. Cleaning and replacing sensors keeps the system accurate.

Credit: www.ebay.com

Diagnosing Cecu Faults

Diagnosing Cecu faults in Peterbilt trucks is essential for safe and efficient operation. The Central Electronic Control Unit (Cecu) controls many truck functions. Identifying problems early helps avoid costly repairs. This section explains how to diagnose Cecu faults effectively.

Using Diagnostic Tools

Diagnostic tools connect to the truck’s Cecu system. These tools read error messages stored in the control unit. Mechanics use scanners or specialized software. They provide real-time data on truck performance. This method saves time and pinpoints exact issues quickly.

Interpreting Fault Codes

Fault codes are short messages from the Cecu system. Each code relates to a specific problem. Understanding these codes helps locate the source of the fault. Repair manuals and online databases list code meanings. Simple codes might indicate sensor issues or wiring problems.

Performing Visual Inspections

Visual inspections complement electronic diagnostics. Check wiring harnesses, connectors, and sensors for damage. Look for loose or corroded parts that affect Cecu function. Physical signs often reveal underlying electrical faults. This step ensures no visible issues are missed.

Quick Fixes For Cecu Problems

Quick fixes for Peterbilt Cecu problems can save time and money. These solutions often solve common issues without professional help. Simple steps like resetting or updating can restore function fast. Understanding basic repairs helps keep your truck running smoothly.

Resetting The Cecu

Resetting the Cecu clears minor errors and glitches. Turn off the truck and disconnect the battery. Wait about 10 minutes before reconnecting the battery. This process resets the system and can fix many faults.

Repairing Wiring Connections

Loose or damaged wires cause Cecu malfunctions. Check all wiring harnesses for signs of wear or corrosion. Tighten loose connections and replace broken wires. Proper wiring ensures accurate signals and system stability.

Replacing Faulty Sensors

Sensors send important data to the Cecu. Faulty sensors lead to wrong readings and errors. Identify the bad sensor by diagnostic tools or error codes. Swap out the defective sensor with a new one to restore accuracy.

Updating Software

Outdated software can cause Cecu problems. Use the latest updates from Peterbilt to improve system performance. Connect the truck to a computer or diagnostic device for update. Regular updates prevent glitches and enhance reliability.

Preventing Future Issues

Preventing future issues with your Peterbilt CECU helps save time and money. Early care reduces the risk of costly repairs. Staying ahead improves truck reliability and safety. Follow simple steps to keep your system in top shape.

Regular Maintenance Tips

Check all connections regularly for signs of wear or damage. Clean terminals and connectors to avoid corrosion. Replace damaged wires immediately to prevent shorts. Schedule routine inspections by a trusted mechanic. Use only recommended parts for repairs and replacements.

Protecting Electrical Components

Keep electrical parts dry and free from dirt. Use protective covers on exposed wiring and modules. Avoid placing heavy objects on cables or connectors. Ensure proper grounding to reduce electrical faults. Store your truck in sheltered areas during bad weather.

Routine Software Checks

Update the CECU software regularly to fix bugs. Use authorized tools for software diagnostics and updates. Monitor error codes and address them quickly. Back up system settings before making changes. Stay informed about new software releases from Peterbilt.

When To Seek Professional Help

Knowing when to seek professional help for Peterbilt CECU problems can save time and money. Some issues require expert diagnosis and repair. Acting early prevents bigger troubles on the road.

Complex Electrical Failures

Complex electrical failures often need a trained technician. These problems include wiring shorts, damaged connectors, or failed control units. DIY fixes may not solve these issues. Professionals use special tools to find hidden faults quickly.

Persistent Error Codes

Persistent error codes in the CECU system show underlying problems. Clearing the codes alone does not fix the cause. If error codes return after resets, professional help is needed. Experts can run detailed diagnostics and fix the root cause.

Warranty And Service Options

Check your truck’s warranty before attempting repairs. Many Peterbilt CECU issues fall under warranty coverage. Authorized service centers provide repairs that keep your warranty valid. Professional service options ensure safe and correct fixes.

Credit: www.ebay.com

Frequently Asked Questions

What Are Common Peterbilt Cecu Problems?

Faulty wiring, software glitches, and sensor failures often cause Peterbilt CECU issues.

How To Diagnose Peterbilt Cecu Malfunctions?

Use a diagnostic tool to read error codes and inspect wiring connections carefully.

Can Cecu Problems Affect Truck Performance?

Yes, CECU faults can cause engine stalls, poor fuel efficiency, and warning lights.

How To Reset A Peterbilt Cecu System?

Disconnect the battery for a few minutes, then reconnect to reset the system.

When Should I Replace The Peterbilt Cecu?

Replace it if repairs fail or repeated errors persist after resets and inspections.

Conclusion

Peterbilt CECU problems can cause truck delays and extra costs. Fixing these issues quickly keeps your truck running well. Regular checks help spot problems early and avoid big repairs. Understanding common faults saves time and money on the road. Stay alert to signs of CECU trouble for safer driving.

Taking care of your truck’s electronics protects your investment. Small efforts now prevent larger issues later. Keep your Peterbilt reliable by addressing CECU faults right away.